| inside sinclair |

On the production line |

Lynd Church goes to Scotland to discover just how the ZX-81 is manufactured

IN KEEPING with its philosophy of sub-contracting all manufacturing processes, Sinclair Research appointed Timex to produce the ZX-81 when it was introduced in March, 1981.

Since that time, production at the Timex plant at Dundee has increased from 10,000 to 60,000 units per month, while production of the Sinclair printer, also in the Timex factory, is now running at 15,000 units per month.

David Chatten, production controller with Sinclair, explained that although the company does not undertake its own manufacturing, it is very thorough in its analysis of prospective component manufacturers. "We get people who are good at manufacturing particular components, then get everything assembled in a good production plant", he said.

The rate of growth of units produced at Dundee not only reflects the success of the ZX-81 but also justifies Sinclair confidence in Timex, a company which had little experience in the assembly of electronic equipment.

Allan Johnston, project manager of board assembly at Timex, explained that the company decided to expand into new technology when watch technology began to change. He said: "Our experience at Dundee was in mechanical watches but development in quartz and digital technology led us to consider expansion into other areas".

So Timex and Sinclair began discussions on the production of the Sinclair flat-screen tube and Microvision pocket TV, for which Sinclair has announced a £5 million four-year capital investment programme. Because Timex had no experience in electronic assembly, it was decided that the production of the ZX-81 would be a first step in the learning process, added to which Timex was prepared to make the capital outlay for equipment needed for such assembly.

Building up the circuit board |

Chatten also stressed that assembly staff at Timex are of very high calibre, the best of whom were, initially, taken off-line to train in ZX-81 assembly. Chatten added: "Getting Timex to do the assembly on the ZX-81 may have been a risky decision in the short term but in the long term it provides us with considerable security, giving us the opportunity to build good working relationships before full production on the pocket TV begins".

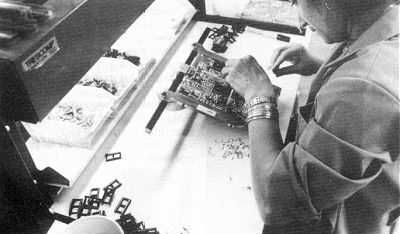

Whatever the risks, production of the ZX-81 seems to be proceeding smoothly, with only minor difficulties still to be solved, according to Chatten. The process starts with the build-up of the printed circuit board, including the addition of diodes and resistors. The board then goes through a flow-solder machine, which solders all the components into place and includes a cutter to tidy the leads.

It is only at this point that the chips are added to the board. They arrive at the Timex plant in anti-static tubes and are fed into a slide dispenser to ease the process of manual assembly. It is at that point that the first test of the equipment is made.

Bearing in mind that the assembly process has not then reached the keyboard stage, the test is to establish that the board is alive and well. It is called the K test, because all it requires is the appearance of the K on the screen, notifying the user that the machine is ready for instructions.

If a board fails the K test, it is then tested on a GenRad 2270 which identifies the fault and produces a printout denoting the area at fault. The printout is then attached to the board, which is returned to the rework section, before going through the entire process again.

Testing for faults |

Assuming that the board has passed the K test, the top half of the casing with the touch-sensitive keyboard and connectors is assembled. At that point, the ZX-81 is again tested, running off a test program on cassette which will display a series of OKs on the screen for every key tested.

Finally, the bottom half of the casing is attached and the completed ZX-81s are packaged for distribution.

There are three main avenues of distribution - Jaserve, a fulfilment house which deals with mail order; Griffin and George, school suppliers; and the W H Smith distribution centre at Dunstable, Bedfordshire. Timex has also agreed recently with Sinclair to market personal computers, peripherals and software in North America.

Distribution for them will be handled by established Timex shipping agents, distribution network and retail outlets in the U.S., though Sinclair will continue to sell the ZX-81 by mail order from its Boston-based subsidiary until Timex sales have reached agreed targets. At that stage Sinclair will begin to concentrate on sales of its yet-to-be-released flat-screen TV.

The machines in North America will be marketed under both Sinclair and Timex names and Sinclair will receive a royalty on all sales under the agreement, which covers current and future Sinclair personal computer products and Timex developments of Sinclair computer technology.

Testing the keyboard |

Timex obviously has a fair amount of confidence in the product it is assembling for Sinclair, demonstrated by its use of the ZX-81 to test the printed circuit board of the Nimslo 3D camera, assembled by Timex and soon to be marketed in the U.S.

Sinclair believes that such confidence is well justified, pointing to what it considers to be a low percentage of returned equipment. The return figure on the ZX-81 is 2.4 percent, though the percentage return on kits is higher, at around 13 percent.

Chatten claimed that the higher figure of kit returns is due more to poor component insertion and bad soldering than to component failure but stressed that if any component failure is found, the £10 which kit customers have to pay for a ZX-81 to be serviced is returned.

He admitted that of the 2.4 percent returns of supplied ZX-81s, around one percent of failure is due to power supply faults, an area in which Chatten believes there could well be improvement. In fact, it is Clive Sinclair's stated aim for a return percentage of one percent overall and it is partly to that end that he recently appointed a quality assurance manager, David Fuller.

While an aim for continued improvement in machine reliability is a necessary part of successful business practice, the gamble of engaging a company with little experience in electronic assembly seems to be paying-off. Chatten commented:

"There is some room for improvement in the assembly process - perhaps greater use of automated production lines - but on the whole we are very pleased with Timex work".